- Our Projects

- wahat Alshimal company

Our company (North Oasis Oil Services Company) is interested in the following projects:

Associated gas processing platform production project, which includes the following production lines:

A. Associated gas processing unit tank production line, including (rolling line, cutting line, bending and welding line, inspection line, etc.).

B. Refrigeration unit (condenser) production line.

The gas and liquefied gas production project includes the following production lines:

A. Liquefied nitrogen gas production line.

B. Hydrogen gas production line.

C. Carbon dioxide gas production line.

D. Support production lines.

The project for the production of glass fiber reinforced with resin (GRE) and its accessories includes:

A. Fiberglass production line.

B. Hardener production line (resin, epoxy).

C. Production line for reinforcing bars (rebars), fiberglass pipes and tanks (GRE), and other construction materials.

Seamless Pipes Production Project

Oil Metering Platforms (SKIDS) Manufacturing and Assembly Line

Design and manufacture of associated gas treatment system using nano-mixing and liquefaction technology

Due to the difficulty of obtaining associated gas processing system technologies in addition to the urgent need for huge transfer equipment that requires time, effort and high cost. The need arose to manufacture and produce this equipment locally with the addition of modern technologies aimed at reducing the processing time and size of the system with the possibility of transfer without the need for expensive.

From this standpoint, our company, Wahat Al Shamal Oil Services Company, has found innovative and modern alternatives to solve the above dilemma by designing and manufacturing processing units that operate with a new innovative technology based on the principle of liquefaction and nano-mixing with the possibility of transferring these units in various fields and the presence of power generation stations specific to these systems that operate on associated gas, which allows greater flexibility without the need for a secondary electricity source.

It is worth noting that the products of this system are highly pure and have a short production cycle, and enable the preservation of the environment by reducing pollution and maintaining the effectiveness of reducing agents

A project to establish a comprehensive, advanced scientific engineering institution with a forward-looking vision that will provide the above projects with all the necessary technical and engineering personnel.

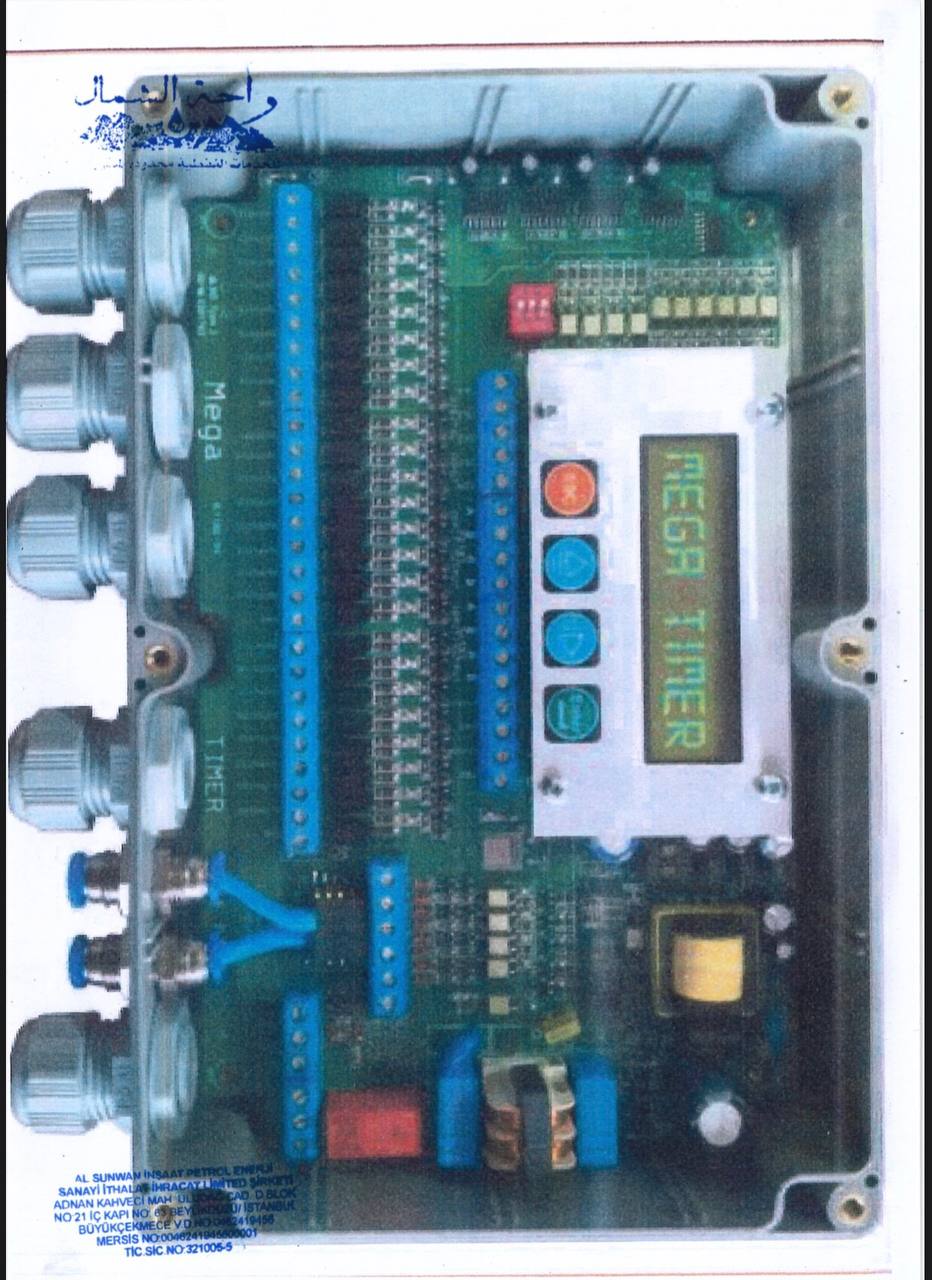

It is worth noting that our company has signed an investment partnership agreement with the Military Industrialization Authority – General Military Industries Company. We were granted a 3,000-square-meter plot of land at Al-Rashid Company, which was used to design, manufacture, and assemble loading and unloading platforms for the oil and gas metering platform project. We also provide PLC/SCAD services and automation systems for petroleum product metering platforms.

Our company has also obtained agencies from supporting companies such as:

Mega (Turkish), Al-Sanwan (Turkish), and Wood World (USA), through its regional agent, Ramallah Engineering Chemical Co.

Through these supporting companies, we have provided the necessary services to the central refineries (Baiji Refinery), Dora Refinery, and Karbala Refinery.

The process of treating gas and associated gas during oil extraction and refining operations is a major leap in the technology of the oil and gas industry in our beloved country Iraq, and gives it a strong boost in the field of sustainable energy, and stops the waste of tens of billions of dollars annually, which enables us to provide returns in hard currency and lead the regional transformation in the Middle East. The success of this process is considered a break in the monopoly of the technology of treating gas associated with oil extraction operations, and will provide a national wealth that strengthens the national economy and ends the stage of dependence on external energy sources and makes Iraq a pioneer in achieving the requirements of the initiative launched by the World Bank, which seeks to reach a level of (zero routine burning by 2030), as this will remove Iraq from the list of countries causing environmental pollution and global warming, in addition to benefiting from gas treatment and providing fuel for power plants and various industrial and service sectors to meet local needs, which will provide self-sufficiency in the future, fill the deficit in the electrical energy system and provide new job opportunities that help reduce the unemployment rate

Below is the electronic platform for downloading fuel.

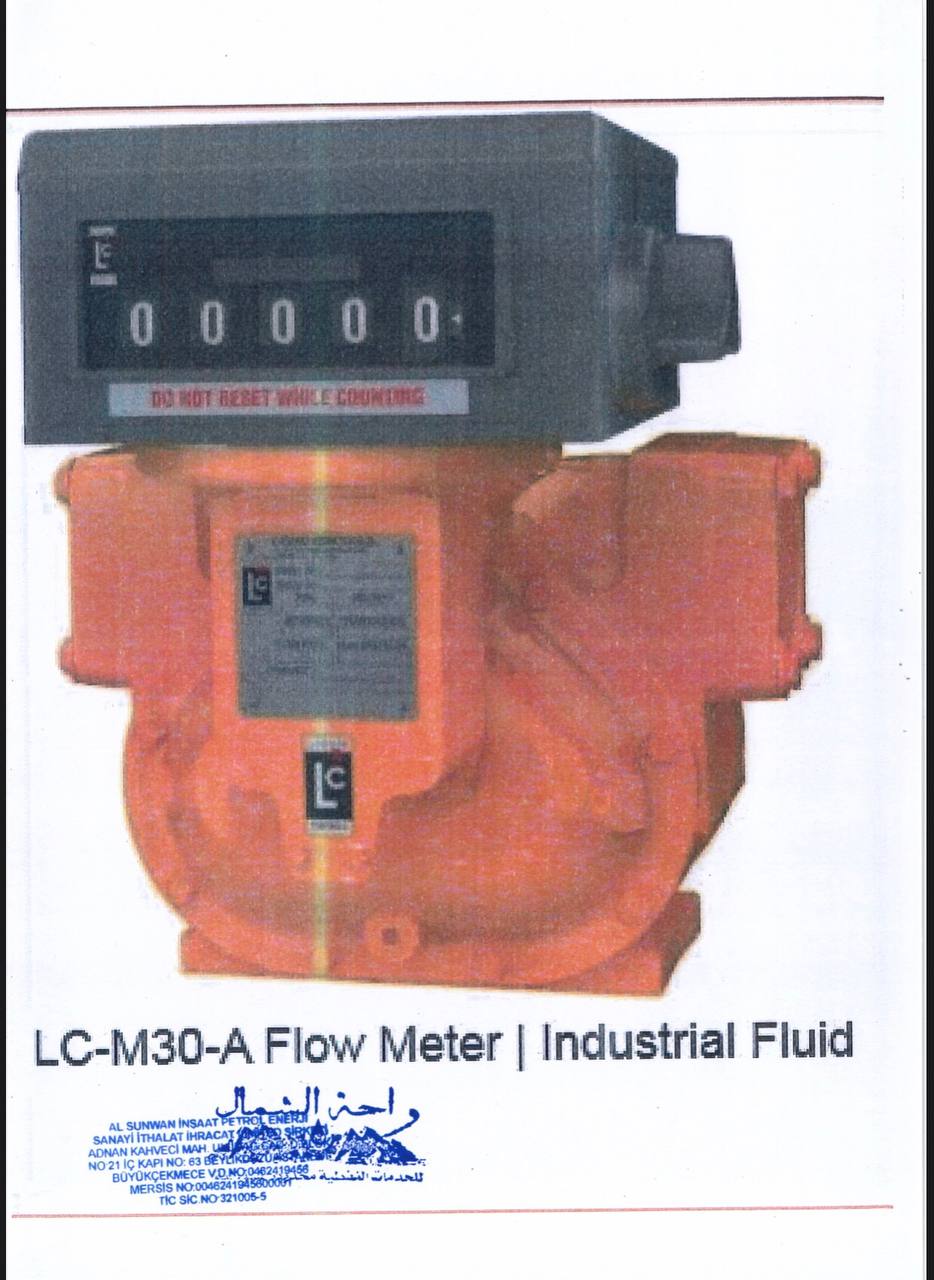

It is a specialized anti-explosion equipment that is controlled electronically by using a transmitter system (remote control) for the purpose of controlling the loading and unloading of fuel from tankers and calculating quantities accurately without the need for manual intervention. This equipment is assembled according to a plan subject to international safety standards (American and British) and installed on a galvanized iron structure to a degree of (450c) with a special grounding system for that purpose.

Platform ComponentsComponentsComponents

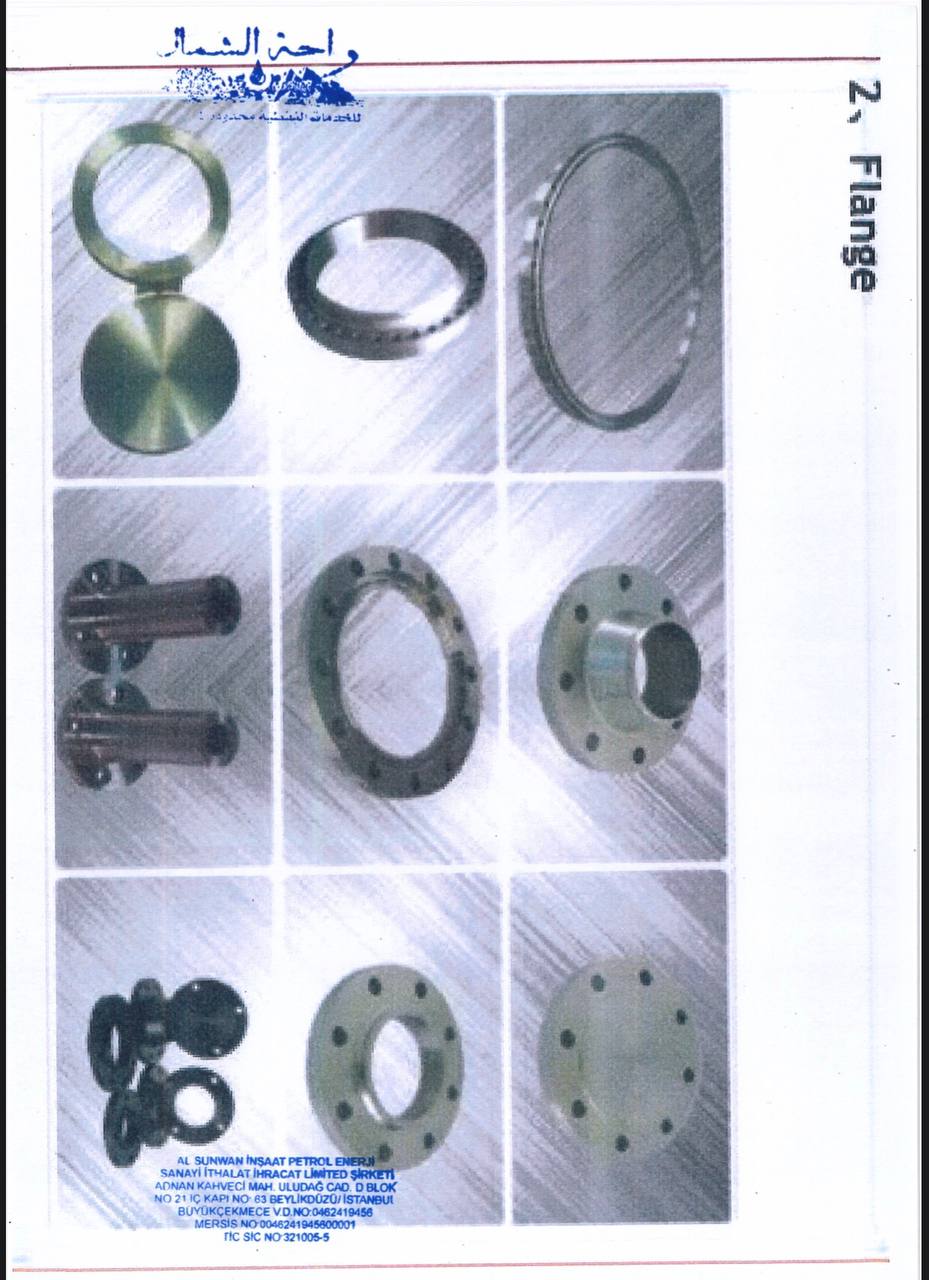

There are more than 5 types of electronic platforms used in loading, depending on the nature of use, fixed or mobile, and most of them share the following main components:

- Galvanized iron structure

- Electronic fuel meter

- Chrome or directional lock

- Filter

- Pressure signal

- transmitter

- Temperature signal transmitter

- Pressure difference signal transmitter

- Non-return valve

- Cable assembly boxes, which are metal, explosion-proof

- Grounding system